In the large family of woodworking machinery, the sliding table saw is a popular “star member”. With its precise and efficient cutting ability, it has become an indispensable assistant in the field of wood processing and plays a key role in furniture manufacturing, decoration engineering and other industries.

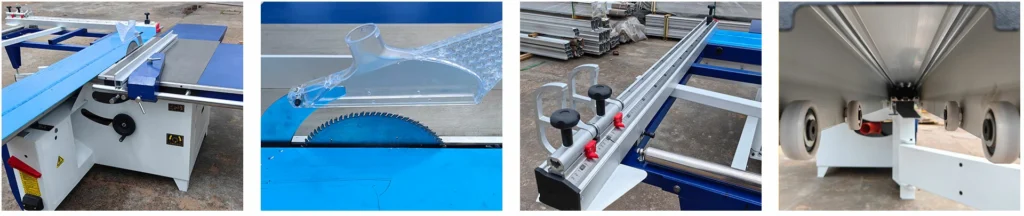

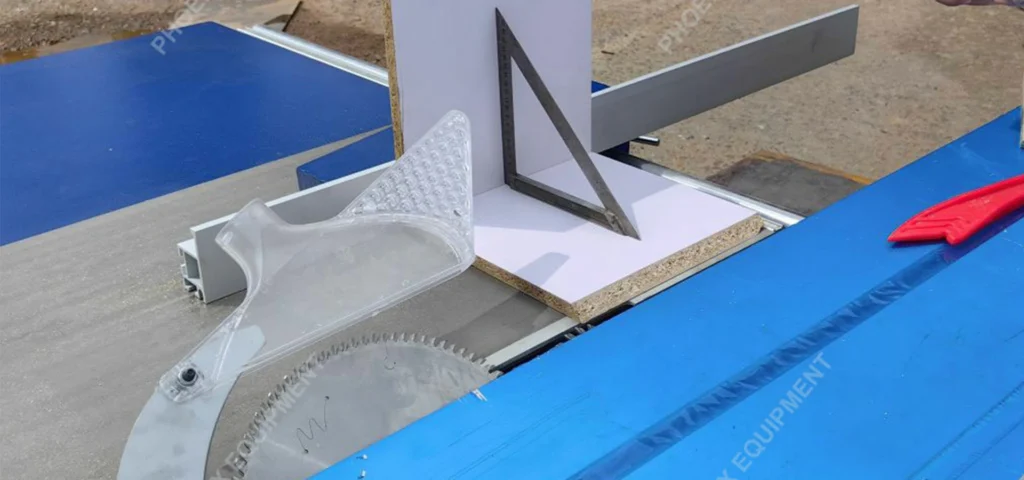

The sliding table saw is mainly composed of core components such as a workbench, saw blade, sliding table, and guide rails. The workbench is a platform for carrying wood, providing a stable foundation for cutting operations; the sharp saw blade is responsible for cutting wood. According to processing requirements, saw blades of different specifications and tooth shapes can be selected to adapt to various types of wood and cutting processes; the sliding table and the guide rail cooperate with each other, and by sliding smoothly on the guide rail, the wood is driven to move accurately toward the saw blade to achieve safe and precise cutting operations.

Compared with traditional manual sawing, the advantages of the sliding table saw are extremely significant. First of all, it greatly improves cutting efficiency. With the help of mechanical power and sliding sliding table, a large amount of wood can be cut continuously and quickly, replacing the slow and cumbersome manual sawing, meeting the needs of large-scale production. Secondly, the cutting accuracy is extremely high. The sliding table moves along the guide rail with very small errors. With the adjustable saw blade height and angle device, whether it is straight cutting or cutting at a specific angle, it can achieve extremely high accuracy to ensure that the size of the processed wood meets strict standards. In addition, the sliding table saw also has good safety. It is equipped with protective devices such as saw blade guards and push handles, which can effectively prevent operators from accidentally contacting the saw blade during operation and reduce the risk of work-related injuries.

In practical applications, sliding table saws can be seen everywhere. In furniture manufacturing factories, it can cut large-sized boards into parts of different specifications, such as table boards, cabinet door panels, etc., laying the foundation for furniture assembly; at the decoration construction site, it can accurately cut wood according to design requirements to meet the diverse needs of door and window production, furniture processing, etc. At the same time, by adjusting the saw blade parameters, the sliding table saw can not only process ordinary wood, but also cut artificial boards, plastic boards, etc., and has a wide range of applications.

However, there are also some things to pay attention to when using a sliding table saw. Operators must undergo professional training and be familiar with the equipment’s operating procedures and safety regulations; regularly maintain the sliding table saw, check the lubrication of the guide rails, the degree of wear of the saw blade, etc., to ensure that the equipment is in good operating condition; keep the work area clean during work, and clean up wood chips in time to avoid affecting cutting accuracy and equipment operation.

With the continuous advancement of technology, sliding table saws are also continuously upgraded. Intelligence and CNC have become development trends. CNC sliding table saws are controlled by computer programs and can automatically complete complex cutting tasks, further improve processing accuracy and production efficiency, reduce manual intervention, and make wood cutting more intelligent and convenient. In the future, sliding table saws will bring more innovations and possibilities to the woodworking industry with more outstanding performance, and promote the industry to a higher level.