In machining and woodworking, complex and irregular contours are often required. Copy milling, with its ability to precisely replicate the shape of a template or master, is a powerful tool for these tasks. By mimicking the template’s contour trajectory, the tool drives the milling process, resulting in a product that accurately matches the template’s shape. This offers significant advantages in the mass production of irregular parts or complex curved surfaces.

Copy milling operates on the principle of “copying.” Its core principle is to capture the template’s contour information through a sensor and convert this information into mechanical motion commands, controlling the tool to mill the workpiece along the template’s contour. Specifically, the machine is typically equipped with a follower contact (also known as a copy finger). As the contact moves along the template’s contour, it transmits displacement changes to the control system. Based on this displacement signal, the control system drives the tool to follow the template’s contour, while the tool rotates at high speed to produce a contour on the workpiece that is identical to the template. This machining method requires no complex programming; simply creating the appropriate templates allows for precise reproduction of complex shapes. It is particularly suitable for the production of small to medium-sized batches or a wide variety of custom-shaped parts.

Structurally, a copy milling machine primarily consists of a bed, worktable, copy mechanism, milling device, drive system, and control system. The bed, serving as the machine’s foundational framework, is constructed of high-strength cast iron or steel, providing stable support for all components and ensuring rigidity and precision during machining. The worktable is used to position the workpiece and template, and can be fed manually or automatically. Some worktables can also be raised, lowered, and rotated to accommodate workpieces of varying sizes and shapes.

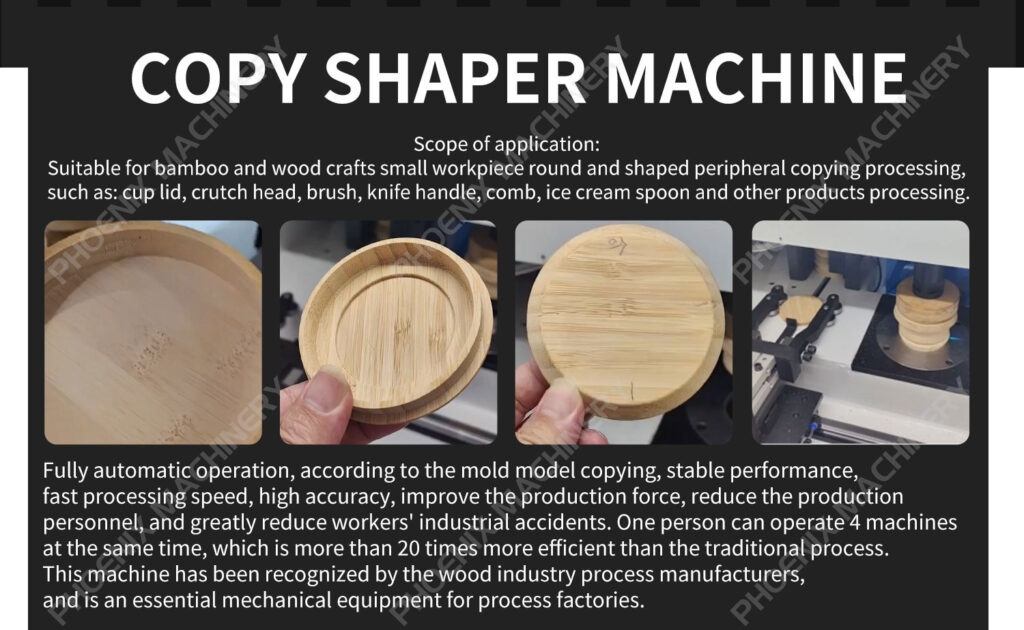

Copy milling has a wide range of applications, and is particularly indispensable in the woodworking industry, where it is widely used in furniture manufacturing to produce various custom-shaped wood strips, armrests, table and chair legs, and cabinet door moldings. By creating various wooden or metal templates, copy milling can quickly produce a variety of beautifully shaped wooden components, significantly improving the efficiency of furniture production and the artistic quality of the finished products.

Compared to other machining equipment, copy milling offers unique technical features. First, machining precision is high. Because the tool strictly follows the template’s trajectory, the shape error between the machined workpiece and the template is typically controlled within 0.1mm, meeting the precision requirements of most industries. Second, production efficiency is high. For batch production of similar irregularly shaped parts, a single template is sufficient for continuous machining, eliminating complex programming and debugging time, making it particularly suitable for small and medium-sized batch production. Furthermore, operation is relatively simple. Operators do not need advanced programming knowledge; they only need to master template installation, workpiece positioning, and basic machine operation, reducing the required skills. Furthermore, flexibility is high. When machining workpieces of different shapes, simply replacing the corresponding template allows for rapid switching between machining types, adapting to the needs of high-variety, small-batch production.