In the modern panel processing industry, demands for cutting efficiency and precision are increasing. Electronic saws, with their high degree of automation and precise cutting, have become core equipment for panel processing. Integrating mechanical, electronic, and pneumatic technologies, they can quickly and accurately cut a variety of panels. Widely used in furniture manufacturing, architectural decoration, packaging, and other fields, they significantly improve production efficiency and product quality.

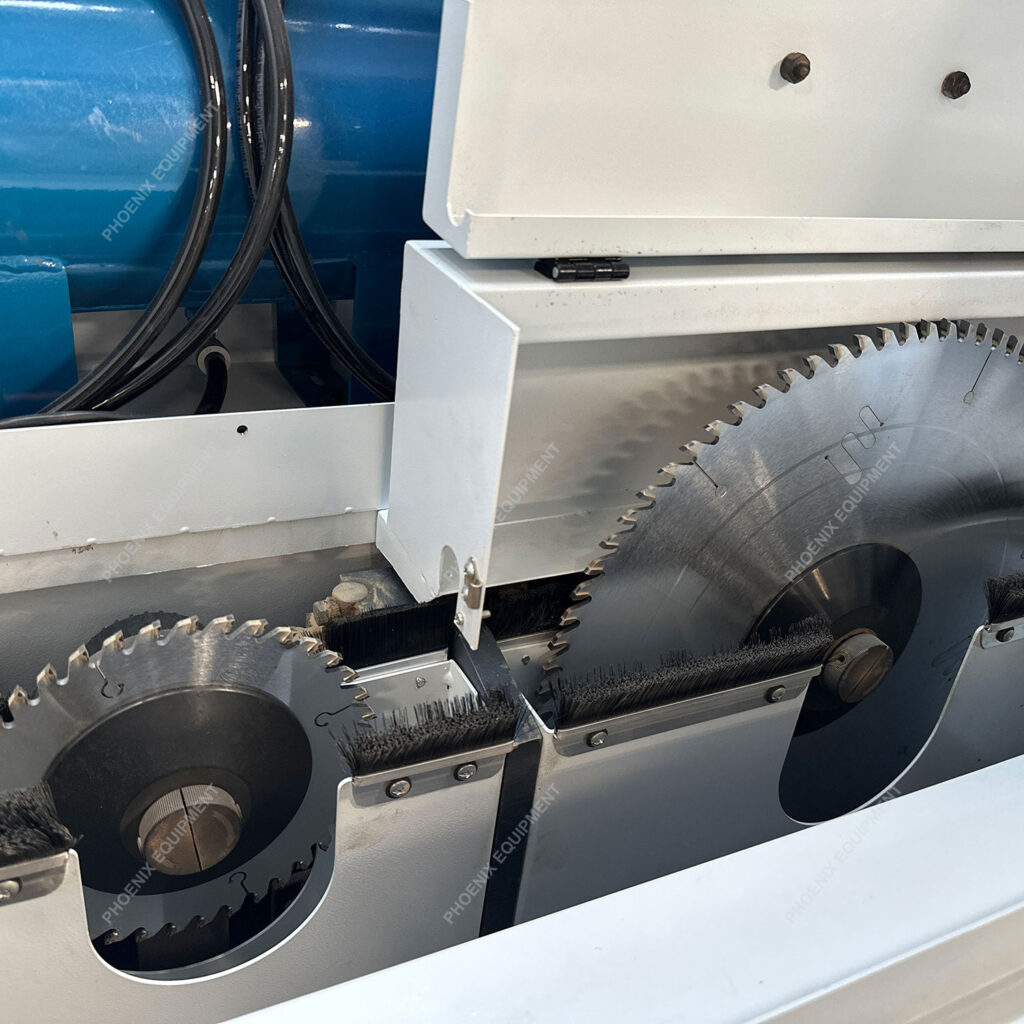

The operating principle of an electronic saw embodies a high degree of automation and intelligence. First, the operator places the panel to be cut on the feed table, where a positioning system performs preliminary positioning. The operator then enters parameters such as the desired cut size and quantity on the control system’s touchscreen. The system automatically optimizes the cutting plan based on these parameters to minimize panel waste. After starting the machine, the feed system conveys the panel to the saw blade at a set speed. The positioning system monitors the panel’s position in real time, ensuring accurate relative positioning between the panel and the saw blade. When the panel reaches the cutting position, the saw blade, driven by the motor, rotates at high speed, while the saw blade system descends or moves along a pre-set trajectory to cut the panel. After the cut is complete, the saw blade resets, and the feed system delivers the cut sheet to the discharge table while continuing to feed the next sheet to be cut, achieving continuous automated cutting. Throughout the cutting process, the control system monitors the equipment’s operating status in real time. If any abnormality occurs, an alarm will be immediately sounded and the equipment will stop, ensuring the safety of both the equipment and the operator.

Electronic saws are widely used in various fields. In the furniture manufacturing industry, they are key equipment for producing panel furniture. They are used to cut side panels, top panels, and bottom panels for wardrobes, cabinets, bookcases, and other furniture, ensuring dimensional accuracy and laying a solid foundation for subsequent assembly. In the building and decoration industry, electronic saws can be used to cut various decorative panels such as gypsum board, aluminum-plastic composite panels, and density fiberboard to meet diverse design requirements. In the packaging industry, they can precisely cut cardboard and wood boards for packaging, producing boxes, pallets, and other products that meet specific requirements.

Electronic saws offer many significant advantages. First, they offer high cutting precision. Thanks to their advanced positioning and control systems, cutting dimensional errors can be controlled to within 0.1mm, far exceeding the accuracy of traditional saws and ensuring product consistency and interchangeability. Second, they offer high cutting efficiency. Electronic saws offer fast cutting speeds and can perform continuous, automated cutting, capable of cutting dozens or even hundreds of panels per hour. This significantly improves production efficiency and makes them suitable for large-scale production. Third, they offer high material utilization. The control system automatically optimizes the cutting plan based on panel size and cutting requirements, minimizing panel waste and lowering production costs. Fourth, they are easy to operate. Operators simply input cutting parameters, and the machine automatically completes the cutting process, eliminating the need for advanced operator skills and reducing operator training costs. Fifth, they offer excellent safety. Comprehensive safety protection systems effectively prevent direct contact between operators and the saw blade, minimizing the risk of accidents.

As efficient and precise automated cutting equipment, electronic saws play an irreplaceable role in the panel processing industry. They not only improve production efficiency and product quality, but also reduce production costs and safety risks, providing strong support for the industry’s development.